Tour de France Bikes: What the Pros Actually Ride

I stayed up way too late one night watching Tour de France highlights on YouTube – you know how the algorithm goes – and found myself pausing on shots of the bikes, trying to read the component specs. That is when I realized I might have a problem. But also I learned a lot, so here we are.

The bikes in the Tour are both incredibly similar to what you can buy and completely different. Let me explain.

The Frame Situation

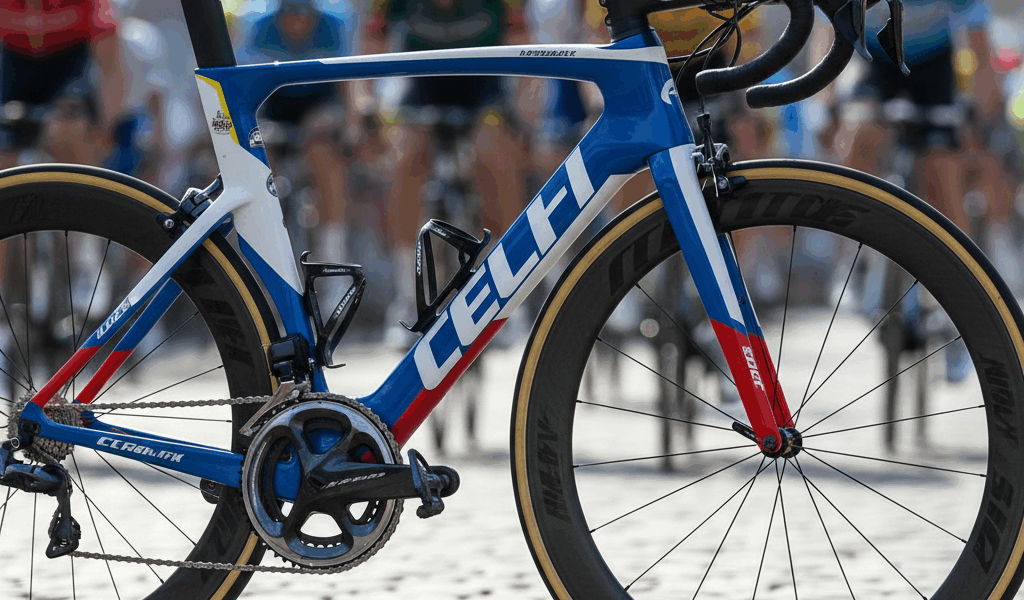

Every bike in the pro peloton is carbon fiber. That is just the reality at this level. Carbon can be laid up in specific ways to balance stiffness, weight, and compliance exactly where the designers want it. No other material offers that level of control.

Most teams ride bikes you can actually buy – Specialized, Trek, Pinarello, Giant, and so on. These are production frames, more or less. The geometry matches what is in the catalog. The differences are in the setup, the paint job, and sometimes special components.

That said, there is definitely some prototype testing happening. You will occasionally see a rider on something weird that is clearly not in any store yet. Those are test mules for next year equipment.

The Weight Rules

Here is something I did not know: the UCI has a minimum bike weight of 6.8 kilograms, about 15 pounds. Many pro frames are actually lighter than this, so teams add weight back to meet the minimum. It is kind of absurd.

This rule dates back to 2000 and was meant to ensure structural integrity. The argument was that the race to make bikes lighter would eventually lead to bikes that break. Twenty-five years later, carbon engineering has advanced massively, but the rule remains.

So when you see a Tour bike, know that it is artificially heavy. If the rule did not exist, some of these machines would be pushing 5 kilograms. That is crazy light.

Electronic Shifting is Universal Now

I do not think I saw a single mechanical drivetrain in the 2024 Tour. Everyone is on Shimano Di2, SRAM Red eTap, or Campagnolo EPS. Electronic shifting is just the standard at the top level.

The pros appreciate the consistent, no-drift shifting. These guys are changing gears constantly – dozens of times per climb sometimes – and electronic systems just keep working without adjustment. Plus the batteries last way longer than you would expect.

The other thing is crash repair. Mechanical cables can get kinked or damaged in a crash. Electronic systems have fewer failure points and can often still work even if the bars get mangled.

Disc Brakes Took Over

This was controversial for a while, but disc brakes won. Almost every bike in the peloton now has disc brakes instead of rim brakes. The stopping power and consistency in wet conditions made it inevitable.

There were some early growing pains – concerns about rotors heating up on descents, weight penalties, that sort of thing. But the engineering caught up. Now disc brakes are just better, full stop.

It also means wheel changes in the neutral support car are more standardized. Everyone runs the same rotor diameters, so any wheel works in any bike.

Wheels for Days

Teams bring multiple wheelsets for different stages. Lightweight climbing wheels for mountain stages. Deep aero wheels for flat and rolling terrain. Time trial specific discs for the individual stages against the clock.

The most common brands are Roval from Specialized, Bontrager from Trek, and some teams run third-party wheels from Enve, Zipp, or Princeton Carbon. These are not the same wheels you buy at retail though – they are often custom builds with specific hub and spoke combos.

Tubeless is common but not universal. Some teams still run tubular tires glued to the rim, especially for racing where support cars can provide instant wheel swaps. Tubeless is better for most applications but old habits die hard.

The Fit is Everything

Pro bike fits are precise to the millimeter. Saddle height, setback, handlebar reach and drop – all of it is dialed based on data from power meters, motion capture, and years of feedback. A pro bike looks uncomfortable to most of us because it is optimized for power output, not Sunday rides.

Teams travel with mechanics who know each rider exact specs. If a rider crashes and needs a new bike, the replacement has to match perfectly. There are stories of riders losing time because a replacement bike was a few millimeters off.

What You Can Actually Buy

Here is the good news: most of what the pros ride is available to regular people. The Specialized Tarmac, Trek Madone, Pinarello Dogma, Giant Propel – these are real bikes you can walk into a shop and order.

The bad news: they cost as much as a used car. A fully spec Tour-level bike runs 12 to 15 thousand dollars, sometimes more. The frames themselves are often 5 to 6 thousand before you add wheels and components.

But the second-tier stuff – Shimano Ultegra instead of Dura-Ace, for example – is like 90 percent of the performance for half the price. And honestly, most of us would never notice the difference.

Does the Bike Make the Rider?

I get asked this a lot when people learn I am into cycling. Would you be faster on a pro bike? Maybe a little. These bikes are objectively faster than what most of us ride.

But the rider matters way more. Jonas Vingegaard on a department store bike would still beat me on the best Pinarello money can buy. The fitness gap is just too enormous. These athletes have spent decades developing their bodies for this one purpose.

The bikes are optimized to not waste any of that effort. Every watt goes into forward motion. That matters when you are racing 21 stages over three weeks at speeds that would kill a normal person. For my Saturday group rides? My current bike is probably fine.

Still Fun to Watch Though

I love the tech side of pro cycling even if I will never ride at that level. The engineering is fascinating – how they balance aero and weight, how they tune ride quality for cobblestones versus mountain roads, how every detail is analyzed and optimized.

And okay, it gives me an excuse to dream about upgrades I do not really need. That deep section carbon wheelset… someday. Maybe.